Asahi Kasei to present easy-to-process particle foam for composite foam core applications at JEC World 2025

Düsseldorf – February 13, 2025 – Japanese technology company Asahi Kasei will exhibit its mPPE particle beads foam SunForce™ at the upcoming JEC World 2025, the leading international exhibition for composite applications, from March 4-6 2025 in Paris. Its combination of high processability and outstanding design flexibility makes it an optimal solution as foam core or sandwich material of composite applications.

Recently, the number of applications of composite materials using foam cores is expanding to reduce weight and increase the stiffness of parts in various industries. However, common composite manufacturing methods such as PCM (Prepreg Compression Molding) and RTM (Resin Transfer Molding) used for producing composite materials generally require high heat resistance of over 100°C in the composite process. Therefore, the number of applicable foams is limited, and most of the high-heat-resistant foams are in block form, requiring pre-cutting, which leads to high processing costs and lower productivity.

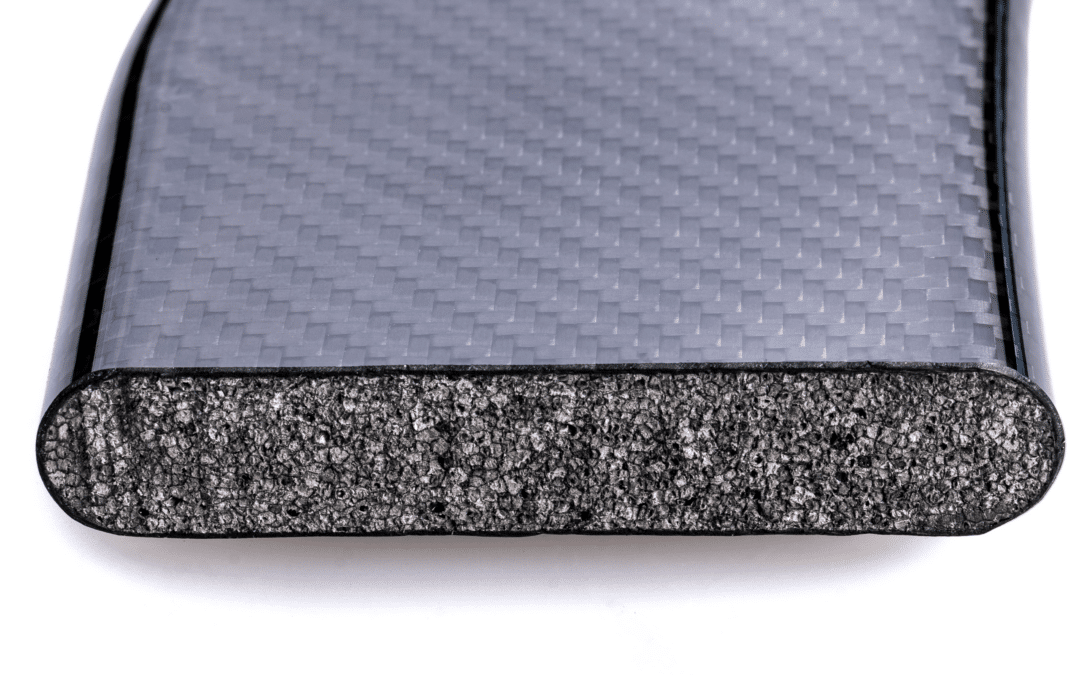

At the JEC World 2025, Asahi Kasei will present SunForce™, a particle beads foam based on the engineering plastic m-PPE (modified polyphenylene ether). This foam features a heat resistance, dimensional stability, low water absorption from the modified PPE, in addition to lightweight, thermal insulation, and formability originating from the bead foam.

SunForce™ beads can be molded by in-mold foaming, utilizing the steam chest molding process. This process in combination with the small-sized beads allows for the medium- to high-volume production of composite core parts with accurate, complex and curved shapes and without the need for additional milling. In addition, m-PPE resin features a low-water absorption.

SunForce™ can be used as foam core or sandwich material for composite applications in the medical, industrial, aeronautical, or sports industry.

Asahi Kasei will exhibit at Booth 6U89.

Visit our Landingpage for more information https://asahikasei.group/sunforce-jec/

About Asahi Kasei

The Asahi Kasei Group contributes to life and living for people around the world. Since its founding in 1922 with ammonia and cellulose fiber businesses, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every age. With more than 49,000 employees worldwide, the company contributes to a sustainable society by providing solutions to the world’s challenges through its three business sectors of Material, Homes, and Health Care. Its Material sector, comprised of Environmental Solutions, Mobility & Industrial, and Life Innovation, includes a wide array of products from battery separators and biodegradable textiles to engineering plastics and sound solutions. For more information, visit https://www.asahi-kasei.com/.

Asahi Kasei is also dedicated to sustainability initiatives and is contributing to reaching a carbon-neutral society by 2050. To learn more, visit https://www.asahi-kasei.com/sustainability/.

Europe Contact:

Asahi Kasei Europe GmbH

Sebastian Schmidt

sebastian.schmidt@asahi-kasei.eu

North America Contact:

Asahi Kasei America Inc.

Christian OKeefe

christian.okeefe@ak-america.com