Asahi Kasei is celebrating the 90th anniversary of its Bemberg™ cupro fiber business – Rebranding launched to mark the occasion

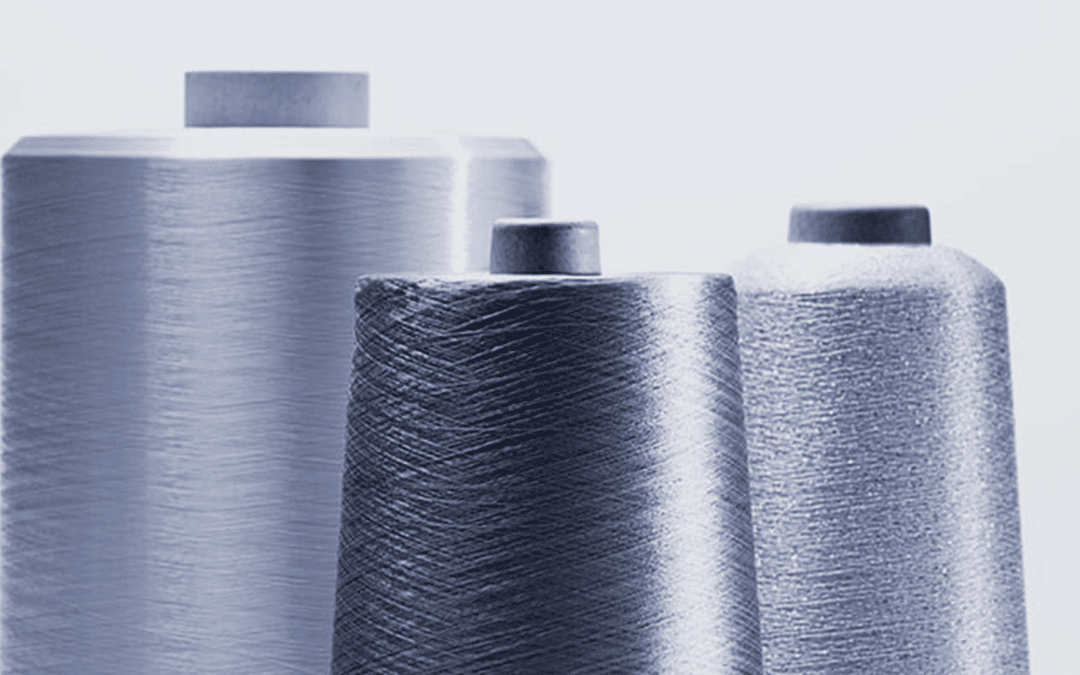

Düsseldorf, 16 December 2021 – Bemberg™ is the brand name of the world’s only cupro fiber, which is manufactured by Asahi Kasei in Nobeoka, Miyazaki Prefecture, Japan. It is used around the world in various applications such as linings, ethnic garments, outerwear, and innerwear.

Being made from cotton linter, a byproduct of cottonseed oil production, as well as being biodegradable and compostable for circularity, Bemberg™ is an environmentally friendly material. Although it is an uncommon material which accounts for only 0.02% of the world’s total fiber production, Asahi Kasei is pursuing value creation and sustainability together with its stakeholders as the only cupro fiber manufacturer. Bemberg™ Senior General Manager, Eisaku Maeda pointed out: “In recent years we’ve been collaborating with new stakeholders, and in the future, we will strive for technological innovation that leads to the improvement of environmental performance and benefits to society. Moreover, we will pursue enhanced added value with Bemberg™ as a one-of-a-kind material in demand throughout the world. “

90-year history of Bemberg™ – Ahead to the next century

In celebrating the 90th anniversary of its Bemberg™ business, Asahi Kasei is looking ahead to the next century by advancing efforts to improve the environment and provide solutions for society. The company is doing so by implementing measures toward carbon neutrality by 2050, strengthening the traceability of raw materials, and developing technology to reduce the environmental burden across the entire supply chain.

“Since the foundation, we have been in the business of transmitting electric power from our own hydroelectric plants, and currently own nine power stations in total. By improving the efficiency of these generators, we will reduce CO2 emissions by approximately 11,000 tons annually and aim to further reduce the environmental impact, “Eisaku Maeda continued.

Cotton linter as the raw material of Bemberg™ is currently procured from partner oil mills – cottonseed oil production factories – located in India, Brazil, USA, and Japan. Bemberg™ staff regularly visits each oil mill to strictly check the production processes and quality of raw materials and keep the quality of the raw material consistent.

Rebranding of Bemberg™

Background

The current business environment is changing rapidly with the need to solve environmental issues on a global scale, efforts such as the SDGs to solve social challenges, and the heightening importance of value creation. In reconsideration of the brand value of Bemberg™ in this dramatically changing environment, the rebranding is performed so that Bemberg™ will continue to be loved by customers and provide value that suits the times.

New tagline

To clearly convey the ideal and meaning of the Bemberg™ brand to customers, the brand is renewed with a new tagline of “Crafted Elegance.”

Crafted: Japan-made cellulose fiber produced exquisitely

Elegance: Not extravagance, but universal beauty

Moving forward with Bemberg™ embodying “Crafted Elegance,” Asahi Kasei will pursue heightened value creation through technological innovation to improve the environment and provide solutions to social issues, leveraging the status of Bemberg™ as a one-of-a-kind material loved by customers.

New Bemberg™ website

The Bemberg™ website is renewed to gain recognition among customers of the new tagline “Crafted Elegance” and its value. The new website will provide information that meets the needs of the times while refreshing the image of Bemberg™ through a renewed design and enriched content.

Milestones: 90-year history of Bemberg™

| 1931 | Start of Bemberg™ production |

| 1940s | Start of production of raw yarn for tricot |

| 1950s | Start of large-scale supply of raw yarn for yarn-dyed linings Start of the industry’s first CHOP (outsourced processing) system |

| 1960s | Start of production of Bemberg™ staple fiber Expansion in apparel and material fields (woven labels, metallic fibers, hair implantation, handicraft yarn, etc.) |

| 1970s | Start of production of Bemliese™ nonwoven fabric Start of production of hollow fibers for artificial kidneys |

| 1980s | Entry to field of outerwear with development of Chezelle™ fibrillated material |

| 1990s | Establishment of Lining Laboratory Discontinuation of hank production |

| 2000s | Expansion of functional materials for innerwear Production of Bemberg™ by other companies ends, making Asahi Kasei the only Bemberg™ manufacturer* * Technology of J.P. Bemberg of Germany had been used by several companies |

| 2010s | Participation in Business Call to Action (BCtA) Acquisition of GRS (Global Recycled Standard) certification |

| 2021 | 90th anniversary of Asahi Kasei’s Bemberg™ business |

Bemberg™ and Bemliese™ are registered trademarks of Asahi Kasei Corp.

About the Asahi Kasei Corporation

Asahi Kasei Corporation is a globally active diversified technology company with operations in the Material, Homes, and Health Care business. The Material division encompasses fibers & textiles, petrochemicals, performance polymers, performance materials, consumables, battery separators, and electronic devices. The Homes division provides housing and construction materials to the Japanese market. The Health Care division includes pharmaceuticals, medical devices, and acute critical care devices and systems. With more than 44,000 employees around the world, the Asahi Kasei Group serves customers in more than 100 countries and achieved sales of 17.3 billion euros (2,1 trillion yen) in the fiscal year 2020 (April 1, 2020 – March 31, 2021).

Asahi Kasei is “Creating for Tomorrow” with all operations sharing a common mission of contributing to life and living for people around the world. For more information, please visit www.asahi-kasei.eu and www.asahi-kasei.com/sustainability/.

Company Contact Europe:

Asahi Kasei Europe GmbH

Sebastian Schmidt

Fringsstrasse 17, 40221 Düsseldorf

Tel: +49 (0) 211-3399-2058

Mail: sebastian.schmidt@asahi-kasei.eu